It's usually an unpleasant situation to be in if you're conversing with someone about something and they are using words or terms of that you simply don't know this is, so before we enter into speaing frankly about hydraulic torque wrenches, let's first start by looking at what precisely a torque wrench is.

A torque wrench is just a wrench designed to utilize a specific number of force (called "torque") to a nut or bolt. When non-mechanical people hear the word "torque" they often think "isn't that like horsepower?" Torque does in fact make reference to force rotating something about an axis (such since the wheels of one's car), but that term can make reference to anything in that situation; not just how powerful your car's engine is.

Another common example involves the lug nuts that hold the wheels on your own car. Lug nuts have a specific number of toque with which they have to be tightened. If inadequate is employed, they might come loose while you're driving which may result in an unstable wheel or the wheel even coming off! If they're too tight you run the danger of something cracking which can also cause the wheels to own problems.

So if these nuts must certanly be applied with a specific number of force (torque), how can one ensure that the right amount of force is employed?

You may make sure the correct number of force is applied using a torque wrench!

Probably the most basic type of this type of wrench includes a little gauge onto it that shows you how much force you're applying. So in this case, if the lug nuts on your own cars require 80 pounds of torque, you put the wrench on and tighten it until it says you're applying 80 pounds of torque, and then you're all set.

There are various types of wrenches like this. The basic kind, as mentioned above, is a wrench with a little gauge onto it, usually with a hook indicating the amount of force being used. Some have mechanisms that keep you from over-tightening past a certain point. These may have a clutch that disengages when a specific amount of force is reached thus preventing any additional force being applied. There are electronic wrenches that have an electronic display instead of an analog gauge. There are also hydraulic torque wrenches that are designed for applying a large amount of force through the use of hydraulics. Sometimes this kind is applied to large bits of machinery where the more basic wrenches wouldn't work.

Aircraft Hydraulics Overhaul

Hydraulic systems troubleshooting varies in line with the complexity of the device and the components in the system. It's, therefore, critical that the technician make reference to the troubleshooting information furnished by the manufacturer.

(1) Relief valves repair... not enough pressure in a method may be caused by a sheared pump shaft, defective relief valves needing repair, regional aircraft control valves, the pressure regulators, unloading valves stuck in the "kicked-out" position, not enough fluid in the device, the check valves installed backward, or any condition that permits free flow back again to the reservoirs or overboard. If a system operates satisfactorily with a surface test unit but not with the device pump, the hydraulic pumps ought to be examined.

(2) If a system fails to hold pressure in the pressure section, the likely cause is the pressure regulator, an unloading valve, leaking relief valves nedding repair, or a leaking check valve.

(3) If the pump fails to help keep pressure up during operation of the subsystem, the pump might be worn or one of the pressure-control units might be leaking.

(4) High pressure in a method might be caused by a defective or improperly-adjusted pressure regulator, an unloading valve, or by an obstruction in a line or control unit.

(5) Unusual noise in a hydraulic system, such as for instance banging and chattering, might be caused by air or contamination in the system. Such noises may also be caused by a faulty pressure regulator, another pressure-control unit, or a lack of proper accumulator action.

Aviation component repair.

Commuter aircraft hydraulics overhaul, maintenance of hydraulic system components, involves a number of standard practices along with specialized procedures set forth by manufacturers such as the replacement of relief valves, actuators, and other units, including tubing and hoses. Care ought to be exercised to prevent system contamination damage to seals, packings, and the rest, and to utilize proper torque in connecting fittings. When installing hydraulic fittings, valves, etc. always lubricate the threads with hydraulic fluid.

Overhaul of hydraulic and pneumatic units is generally accomplished in approved repair facilities; however, replacement of seals and packings may be achieved from time to time by technicians in the field. When a unit is disassembled, all O-ring and Chevron seals ought to be removed and replaced with new seals. The new seals must certanly be of the exact same material as the original and must carry the correct manufacturer's part number. No seal ought to be installed unless it's positively identified as the correct part and the shelf life has not expired.

When installing seals, care ought to be exercised to make sure that the seal isn't scratched, cut, or elsewhere damaged. If it is necessary to install a seal over sharp edges, the edges must certanly be covered with shim stock, plastic sheet, or electrical tape.

The replacement of hydraulic units and tubing usually involves the spillage of some hydraulic fluid. Care should be used to make sure that the spillage of fluid is kept to the absolute minimum by closing valves, if available, and by plugging lines just after they are disconnected. All openings in hydraulic systems ought to be capped or plugged to prevent contamination of the system.

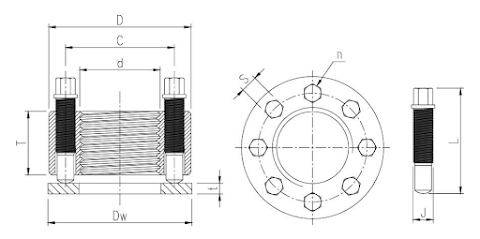

The significance of the appropriate torque placed on all nuts and fittings in a method cannot be over-emphasized. A lot of torque will damage metal and seals, and inadequate torque can lead to leaks and loose parts. The proper torque wrenches with the appropriate range ought to be utilized in assembling system units.

Impact Wrenches - How to Choose the Right Tool

Impact wrenches are powered socket tools, powered by compressed air or electricity, they are one of the most common and useful tools in the professional, and serious amateur workshop. Impact wrenches work by spinning a "hammer" to a high speed, and then suddenly engaging the socket, to supply an immediate burst of torque. While electric (both mains and cordless) and hydraulic models are available, it's the air impact wrench which is by far probably the most popular.

Air impact wrenches are by far the most popular of most air tools, and if you're doing any serious number of automotive work you'll definitely want one. When you rush out and create a purchase however, there are always a handful of considerations - power source, and socket size. Power source depends on your allowance, and what tools you already have. Socket size depends on the sort of work you're doing.

As mentioned previously, air impact wrenches are by far the most popular, but that doesn't mean they are your only choice. While they are relatively inexpensive, and offer good power, they do need a compressor as an electric source. Unless you curently have the right compressor that may add a considerable amount to the price of the tool. In the event that you don't have the right compressor, and are doing only occasional or light automotive work (such as in a house workshop) then an electrical or cordless wrench is probably a better bet. These days the cordless wrenches are more than capable of light work, and are reasonably priced.

Your other main choice is going to be socket size. Most impact wrenches can be found in sizes from 1/4" to 2" and even larger. For the home workshop a 1/2" is generally sufficient, with a 1" drive being more desirable if you're working on SUVs or light commercial vehicles. If you're working on big rigs a 2" drive may be needed. Larger than 2" is generally only employed for industrial purposes.

There is another choice if you ask me made, and that's style. The smallest wrenches are shaped such as for instance a screwdriver, but they are only capable of delivering low torque. Most 1/2" wrenches are of the "pistol grip" variety, shaped like an electrical hand drill. As you move up to heavier duty tools you'll start to come across D and T grips which permit a much firmer hold, and so higher torque levels. The right style for you personally depends on the sort of work you'll be doing, so take that into account when creating a purchase.

Be Familiar With Ingersoll Rand Impact Wrench

Impact wrench is amongst the practical inventions in the 21st century in the industry of home appliances that assist in offering a high torque in a rock or wall with the use of compressed air or electricity. This wrench, also called air wrench or torque gun is actually a powerful instrument which produces high torque with minimum energy getting for the consumer. And once putting it that way, you've got no other option and yet to such as this tool.

The ability in this wrench was traditionally due to compressed air but more recently the accessories use hydraulic as well as electric power to produce a whole lot more if not similar level of energy. The wrenches that use compresses air are usually called pneumatic impact wrenches. However nowadays, one is more prone to discover cordless electrical wrench since the tool of choice of most tool lovers.

Both equally, the electrical and air-powered impact wrench functions precisely the way in which manual wrenches function. The sole variation in each of these certainly is the foundation of power. Within the electrical impact wrench, upon pulling the trigger, the tiny hammers in the wrench are often impacted and get into a rotary movement. This specific movement enables the wrench to execute its activity and causes minimal effort to be put in position manually. Needless to say, that the electrical and air-powered impact wrenches works considerably faster.

These tools should really be used with caution as well as safety. One needs to understand his/her needs and understand the appliances prior to utilizing them for regular or critical jobs. The most common troubles confronted by amateurs and newbies are cross threading and to over-torque the actual bolts than required. Therefore if you should be new at utilizing an impact wrench, it would be recommended to hand-tight the screws just after using this wrench.

This Wrench is well known and liked for the multipurpose usages such as for instance auto repairs, production lines, manufacturing of heavy equipments, construction projects etc. A guitar kit is deemed as inadequate as well as incomplete without the need for excellent, strong impact wrench.